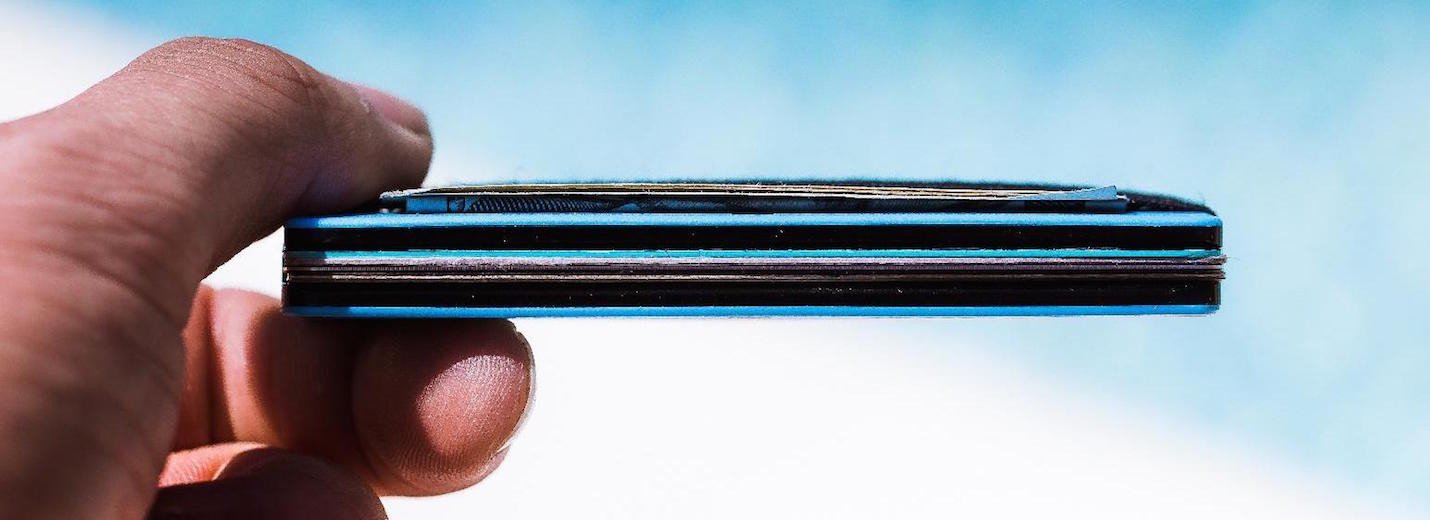

Carbon fiber is known for its durable weave. Titanium is almost synonymous with strength. Aluminum is the lightweight metal planes are made of, and polycarbonate has a reputation for stopping bullets.

We make our wallets out of these materials, so our wallets are known for their durability…

However, a question remains: How strong is The Ridge exactly?

Let’s break it down by material.

Before we throw some sick stats at you, let’s discuss our key metric: Tensile strength.

In plain speak, tensile strength is the amount of pressure a material can take before breaking under tension.

Now, there are tons of factors that could affect the overall durability and strength of these materials. The thickness, shaping, areas where screw holes are installed, temperature, etc. There are also other metrics to consider, like elasticity, hardness, modulus of elasticity, and so on.

BUT, we’re going to give you thebasic breakdown, while ultimately focusing on tensile strength.

Polycarbonate is the only non-metal material in our wallets. Don’t let this plastic fool you, though. This is the kind of stuff bullet-proof glass is made of. Polycarbonate polymers are also some of the highest heat-resistant plastics available – with a melting point of 311 degrees Fahrenheit.

The military uses polycarbonate for their jet canopies. We use it for our wallets.

Polycarbonate’s tensile strength: 9.19 KSI

That’s a grand total of 9,190 PSI - or about 4,000 more psi than the strongest biting animal on Earth: The Nile Crocodile.

Bullets, high-speed flights, and crocodiles – We’ve got you covered. Not to mention, inside of our polycarbonate wallet rests two layers of…

As the second-most used metal in the world, everyone’s been exposed to this light-weight, durable material. Aluminum is super corrosive resistant, highly ductile, and used in nearly everything aeronautical.

Yeah, it’s also used in Coke cans, too. So, what?

Aluminum’s tensile strength: 45 KSI

Or, 45,000 PSI… Or, a little more than the projected bite force of Megalodon… Whichever helps you remember best.

Known as the “workhorse” of titanium, grade 5 titanium is used extensively in aeronautical, offshore, and automotive industries. It’s much stronger than pure titanium, while maintaining the same stiffness and heat properties. Grade 5 is also known for its ability to withstand environmental weathering – that’s why it’s usually the metal of choice for offshore oil drilling and aeronautical engines.

Grade 5 titanium’s tensile strength: 138 KSI

Or, 138,000 PSI.

Yeah, we’ve got wallets made from the same stuff they make jet engines with.

3k Carbon Fiber Weave 3k carbon fiber weave’s tensile strength: 610 KSI.Carbon fiber is a sleek, super durable material. Thousands of tiny strands composed of carbon atoms are woven together to create a yarn, which is then woven again, and filled with epoxy to create the material we use in our wallets.

3k carbon fiber weave’s tensile strength: 610 KSI.Carbon fiber is a sleek, super durable material. Thousands of tiny strands composed of carbon atoms are woven together to create a yarn, which is then woven again, and filled with epoxy to create the material we use in our wallets.

That means that the carbon fiber material we use in our wallets can withstand 610,000 PSI (pounds per square inch) without breaking.

That’s about 15X a Megalodon shark’s biting force…

A .300 Weatherby Magnum, at its peak muzzle velocity, only puts out 60,000 PSI.

So…. Yeah. Good luck snapping this Ridge. Or, any of them, for that matter.